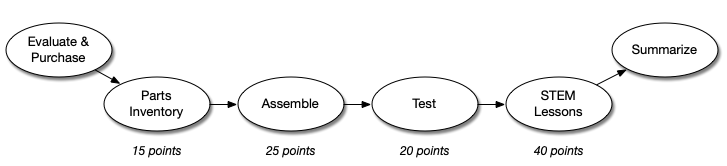

Amblit Technologies’ robot STEM kit evaluation & scoring process is using a six (6) step process as depicted in the diagram above. Four (4) of the six (6) earn up to a total of 100 points. All steps, even those without points, are scored on 0 (terrible) to 10 (great) experience score. For a kit to earn all 100 points, they need a 10 evaluation score on the steps with points.

Evaluation & Purchase

Amblit Technologies is continually surveying the available robot STEM kits across different retail outlets and manufacturer stores. Ideally we would like to find, buy and evaluate a representative kit from all the manufacturers of robot STEM kits that are either computer or programmable controller based, and cost less than $1,000. We will make exceptions from time to time. We also accept requests, which are then added to our initial evaluation queue. Currently we don’t have a limit on the number of kits and their supporting accessories (computer, batteries, …) we will purchase, but we currently only support five (5) active kit evaluations at a time.

We currently are NOT participating in any affiliate marketing or manufacturer programs so as to remove any potential bias that may enter into our evaluations. Again, our goal is to recommend the best possible experiences for students and teachers, while helping manufacturers improve their offerings.

Every kit after purchase starts with a zero (0) score, even if we have had difficulty in making the purchase or obtaining any required accessories.

Summarizing for a kit to be considered for evaluation:

- Advertised by its manufacturer to be a robot kit that includes some sort of assembly

- Must include either a programmable computer or controller

- Include STEM related lessons for the kit builder/assembler

From time to time we will consider and review other types of related products, devices and kits that are related to robotSTEM kits.

Parts Inventory

Before assembling any kits, a quick reading of the instructions and an inventory of the parts should be made. The following are key to a great kit and kit assembly experience:

- Do the instructions include a detailed list of the parts with counts of the individual parts?

- Are the parts instructions clear and readable?

- For similar and complicated parts, are there pictures, diagrams and/or labels that identify those parts?

- Are like parts (e.g., screws, nuts, washers) in their own bags or containers with easy-to-read labels?

- With parts that have a specific orientation in the assembled kit (e.g., top, bottom, left-side, …) is the part orientation clearly labeled?

- Some parts need to be tested before assembly. Are these parts properly labeled and the test with success criteria clearly described?

- Are all of the parts included?

- For very small parts that are difficult to install (e.g., tiny screws and nuts), are there extra in case one/some are dropped and lost?

- For large, complicated kits is there a description of how the parts should be organized and laid out to make the assembly process easier and helpful in avoiding assembly mistakes?

The Parts Inventory evaluation is worth 15 points. Scoring in this section starts with those points. If one of the criteria is not met, one or more points is deducted from the score. It is possible to end up with a negative score.

Kit Assembly

A great kit to assemble is one with:

- Easy to read, clear instructions that both tell and show how to do each step

- Parts are well made and fit together cleanly unless clearly documented

- For complicated assemblies, there is a video that shows in detail how things fit together (i.e., kit part explosion) or how to actually assemble key steps. The video(s) should be constructed and document in such away that enables the kit builder to go to the desired section, and to replay it multiple times if need be. On a complicated assembly its no unknown to have certain sections replayed more than a dozen times and in slow motion.

- Sections of kit are assembled and then the assemblies are assembled together providing clear stopping points during the overall assembly process.

- Relatively to install screws, nuts and washers (we acknowledge that big, clumsy hands and bad eye sight can make kit assembly more challenging, but even they should be able to use bright lights, magnifying glasses and tweezers to assembly those difficult parts)

It is important to identify the more difficult sections and give tips on how to complete the step(s). If an estimate is given on how long it takes to complete the kit assembly, also the skill level of the person who could do it in that time. Managing the kit builders expectation is a key element of the overall assembly process.

The Kit Assembly evaluation is worth 25 points. Evaluation starts with a zero score and then added and subtracted as the build progresses.

Kit Testing

A great kit has a test plan independent of any lesson or instructional documentation. The test plan:

- Demonstrates that each key component and/or assemble works the way the manufacturer meant it to work. For example, in a moveable kit, can it go forward, backward, left and right on command. Does it start and stop? There is a checklist for each activity test.

- If a test fails, there are written directions on either how to make the appropriate adjustments, perform further tests to determine what caused the problem, and what to do if the kit assembler cannot successfully resolve the issue

- If a test fails, the test plan indicates what other tests can be performed to complete as much of the testing before contacting the manufacturer, dealer or service company with all of the issues versus one at a time in a serial fashion.

- Extra credit will be given on complicated tests if there are explanations given that describe why the test is being done, what is important about it and if there is an range where the results are acceptable, why it is only that range.

The Kit Testing evaluation is worth 20 points. If there is a test plan, the evaluation score will start with all 20 points. Points will be taken away for incomplete and missing tests, poor documentation, and slow response from the manufacturer, dealer or support organization if/when problems occur. If there is not a formal test plan, points will be awarded on passed tests that have adequate documentation.

STEM Learning / Lessons

Lessons need to be written for the target audience. The introduction to the lessons should identify the target audience characteristics including their age range, background knowledge and robot kit skill level (i.e., beginner/novice, moderate, expert). The introduction should summarize what the student will learn after completing all of the lessons.

Lessons need to be well written and clear. Lessons written in English must be grammatically correct.

Lessons should provide references to background material to enable a student to learn more in depth information. If a lesson involves complex terms or terminology, include a reference glossary.

There should be a lesson for each major function or robot capability. If programming is involved, program code should be clearly documented and follow standard syntax and programming standards. The program code should be consistent across program files, listings and modules. If complex formulas are used, references to detailed descriptions of how they work must minimally be included.

At the end of all lessons a lesson summary should provide suggestions of what student should pursue next based on their different interests.

The STEM Sessions evaluation is worth 40 points since it is the most important of all of the sections. Points for Lessons will be both earned and lost. Extra credit will be earned for unique and original work.

Summary

The Summary will include all the positive and negative aspects of the kit assembly, testing and learning experience. It will include recommendations of to improve the kit and that experience, and highlight how a student can continue learning through the use of the kit.

The summary will also include the overall score given to the kit.